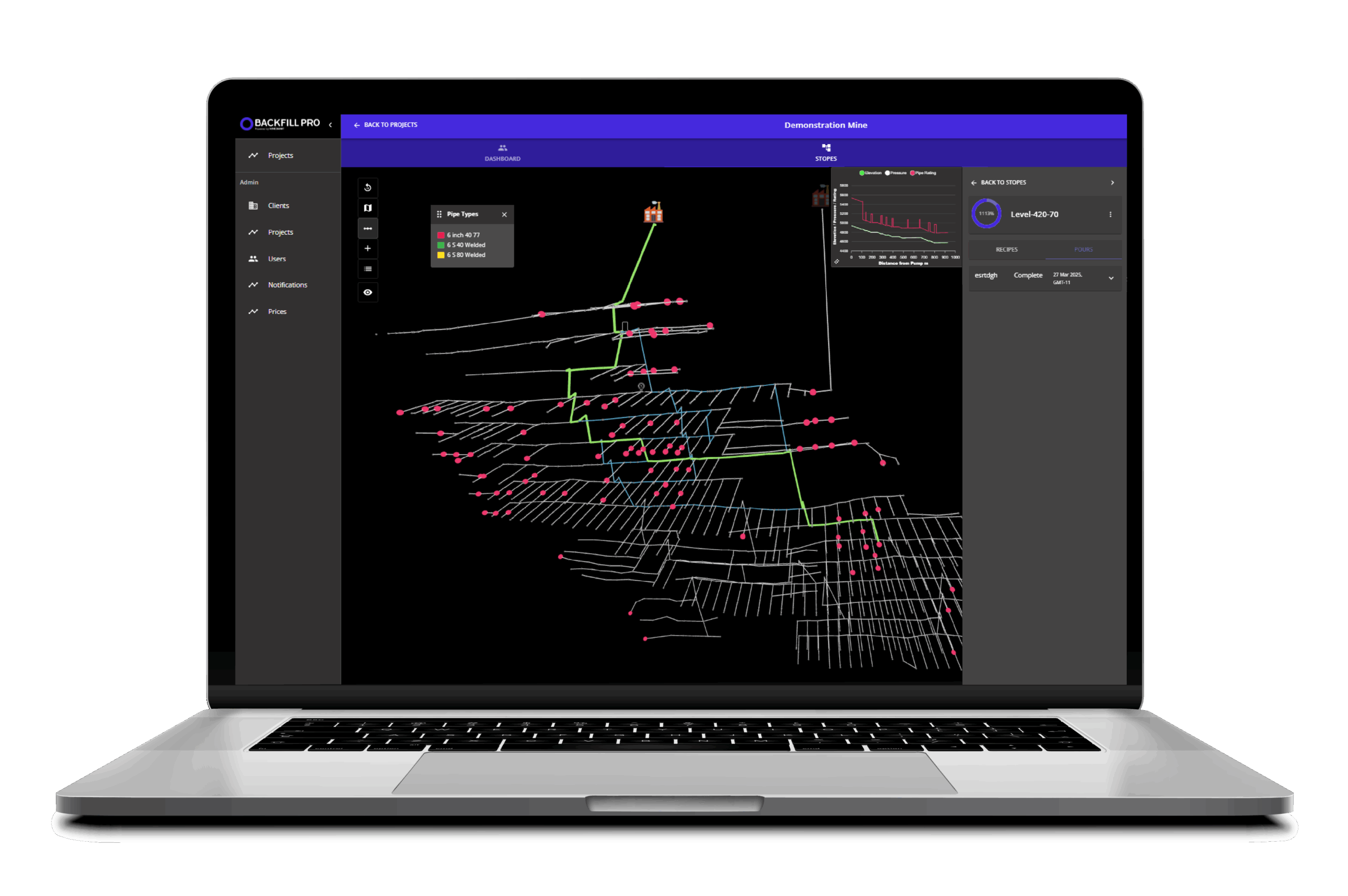

What is Backfill Pro?

Backfill Pro is a cloud-based engineering software designed specifically for underground mines using paste backfill. The software is customised to each mine’s unique underground layout and backfill reticulation system, ensuring users gain maximum value for their specific operation.

Backfill Pro provides the visibility and control engineers need.

Developed with Paterson & Cooke's world leading backfill and hydraulic design expertise, it helps you to define and optimise your paste recipes, generates and controls Hydraulic Grade Lines, tracks, records and uses your QA/QC data, while also centralising operational data into one tool.

How It Works

'Designed by Engineers, Perfected by Backfill Experts'

-

Model and Optimise

Generate & control your Hydraulic Grade Lines, find and optimise tailored paste recipes for each pour.

-

Analyse and Predict

Identify risks such as slack flow or overpressure, enable predictive material maintenance.

-

Connect and Monitor

Integrate live data and monitor what matters in real time.

-

Collaborate and Comply

Document repository and approval workflow. Track, record and use your QA/QC data.

Key Features

Backfill Pro offers a core package, as well as optional expansion modules, to create a software solution purpose-built for your operation.

Predict system behaviour under different flow rates and paste properties

Overlay predicted versus actual pressure

(when live data is connected)

Set limits and generate alerts for slack flow, overpressure and pump limits

Export hydraulic results for reporting and troubleshooting

Validate network performance before pour execution

Simulate pumpability and pipe friction losses for different recipes

Store and compare recipes across multiple stopes

Link recipe to QA/QC, UCS database for strength performance validation

Generate binder consumption forecasts for costs planning

Export recipe specifications for laboratory or plant use

Zoom into branches, nodes, valves, and stopes for clarity

Highlight active lines during pours and track flow direction

Show throughput history on each section of the circuit

Directly modify node connections to match design changes

Integration with the Hydraulic Grade Line to display live predicted versus actual behaviours

Quick view of active pours, planned pours, and stope fill status

Alerts for hydraulic limits, QA/QC non-conformance, and wear thresholds

Graphical display of UCS trends, binder usage and throughout volumes

Customisable widgets per user role

(engineer, manager, lab)

Live sensors integration to overlay plant data in real time

QA/QC reports with UCS results, trendlines, and non-conformance alerts

Hydraulic-simulation reports with predicted pressures and flow rates

Wear monitoring reports by line, branch or inspection points

Compliance-ready reporting for regulatory or management review

Upload pour records, compliance approvals, lab certifications, SOPs, fill note and manuals

Tag documents by stopes or project for quick retrieval

Role-based permissions for secure access (engineer, lab, manager)

Version control and audit trail for all uploaded documents

Searchable repository for easy access during audits or troubleshooting

Model

Optimisation

View

Upload

Expansion Modules

Direct importing on DXF and DUF strings and properties

Connecting and deleting nodes

Bulk changing of pipe type

Generate breaking schedules for ongoing pours

Database of all UCS values connected to stope and pour

New lab user role for direct QA/QC access

Automatic WC : UCS graph generation (coming soon)

QA/QC result alerts (coming soon)

Thickness measurements for inspection points

Wear rate calculations based on forecast system utilisation

Predictive thickness analysis

Schedule-based predictions (coming soon)

Calculate stope volumes

Plan pours based on fill height

Visualise individual pours

Live Hydraulic Grade Line with actual versus predicted pressure

Slack flow and overpressure limit monitoring

Flushing pressure calculations

Volume and flow rate optimisation

Module

Module

Module

(coming soon)

(coming soon)

(coming soon)

Designed to Deliver Value for All Stakeholders in Your Backfill Operation

Confidence in stope fill design and pour planning

Quick access to QA/QC data and recipes

Reduced time spent in spreadsheets and manual reporting

Fewer unexpected shutdowns due to hydraulic issues

Visual tools to explain backfill plans to supervisors

Data-driven decision support on site

Improved operational efficiency and throughput

Lower risk of costly failures or delays

Stronger compliance and safety oversight

Single source of truth for backfill operations

Higher adoption by engineering teams

Predictive capabilities for long-term cost savings

Request a Demo

Get in touch to setup a Demo of our Backfill Pro software solution.